Solutions

Below is a list of a few of our featured solutions. This list is just an example of our capabilities. See our full list of services and areas of expertise here.

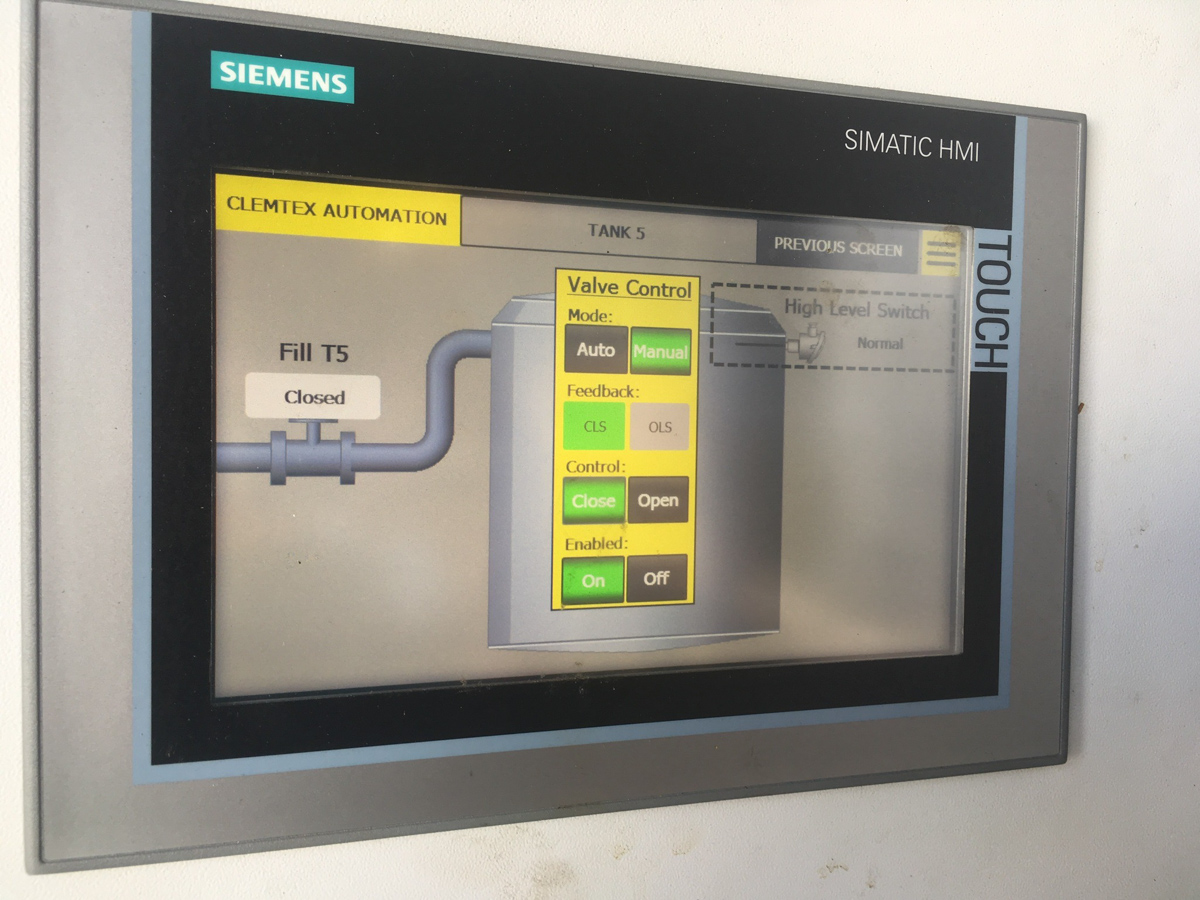

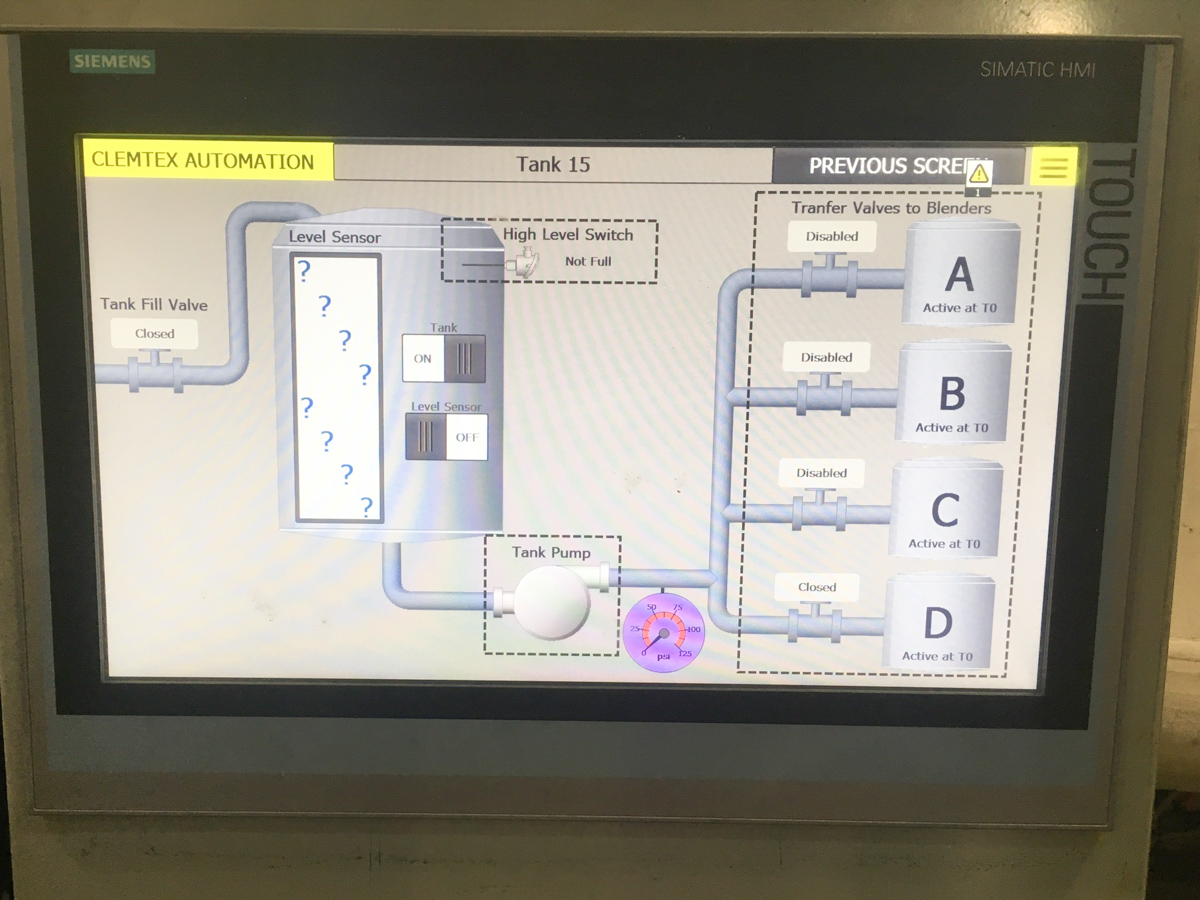

Fluids Mixing Plant Control System Upgrade

- Burdened with severely outdated controls, this customer contacted us to do a full plant upgrade of their control system. This chemical mixing plant creates various products by mixing chemicals into large blending tanks. Their facility contains multiple mix tanks and chemical storage tanks. The full system consisted of more than 100 valves and 20 pumps. The system’s I/O included valve actuation with feedback, pump control, weigh system feedback, level sensors, pressure transmitters and more.

- Clemtex’s team of engineers designed, programmed and installed a new automated control system to the customer’s specifications. The images show the main control panel before and after the installation.

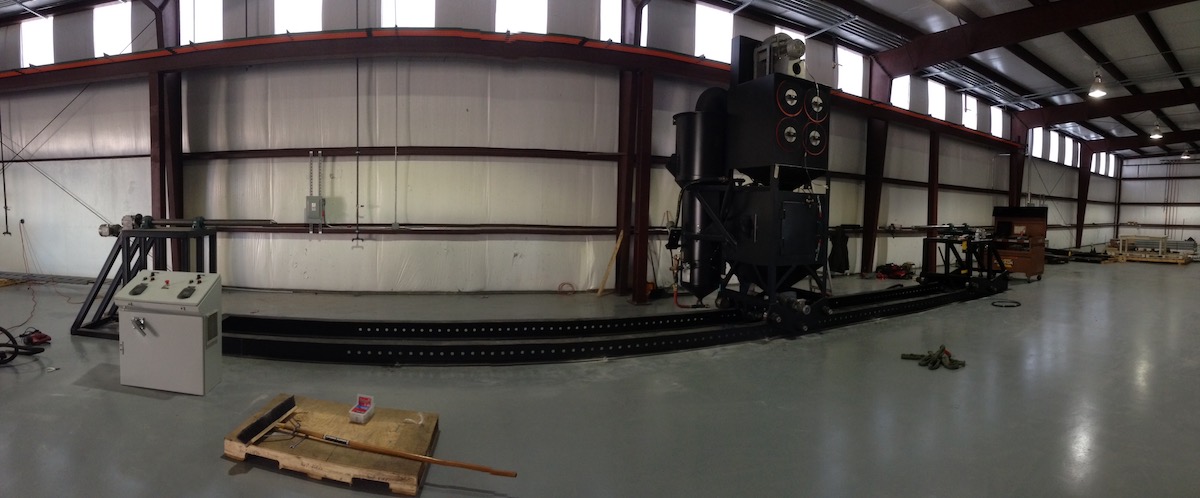

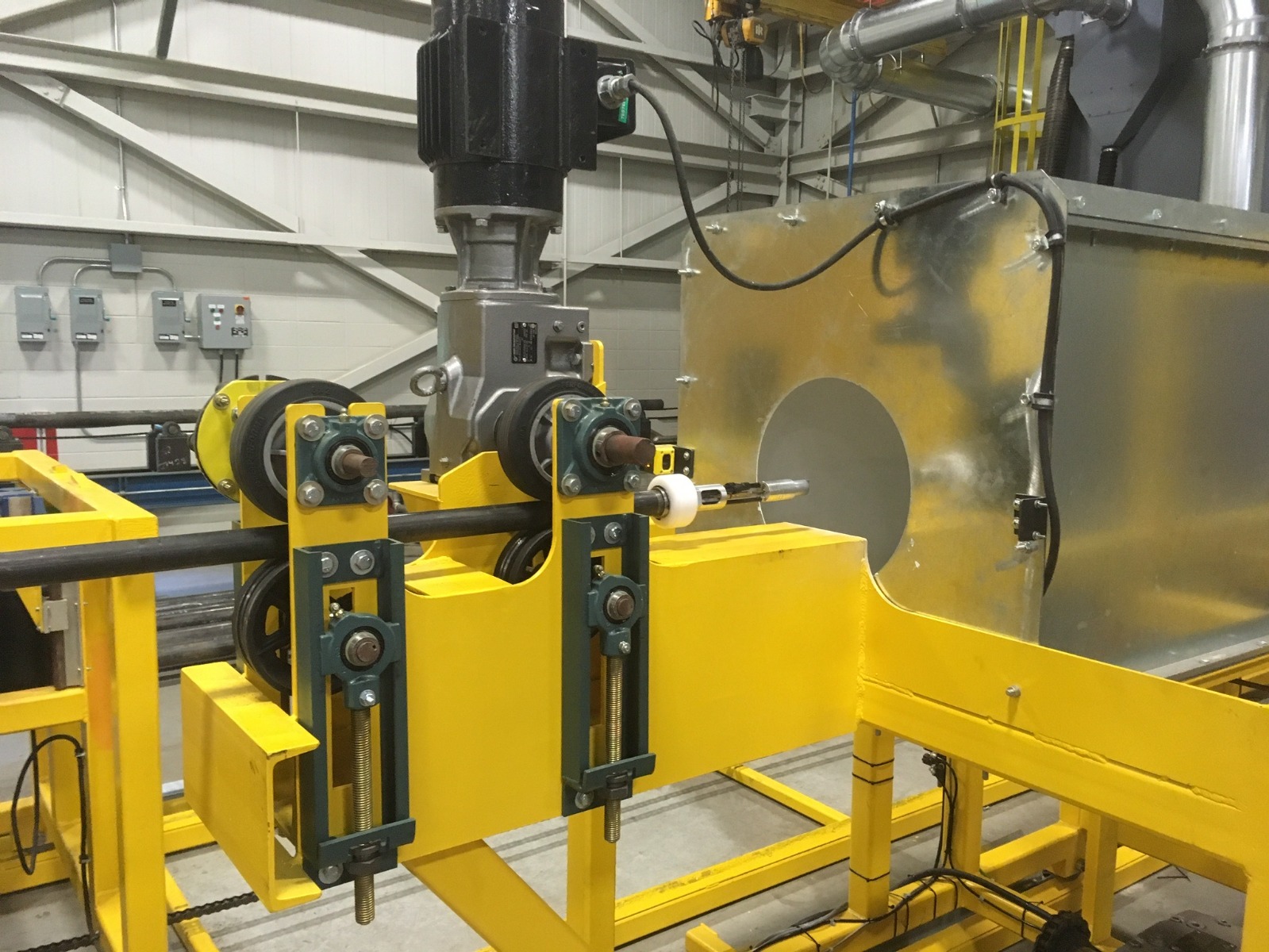

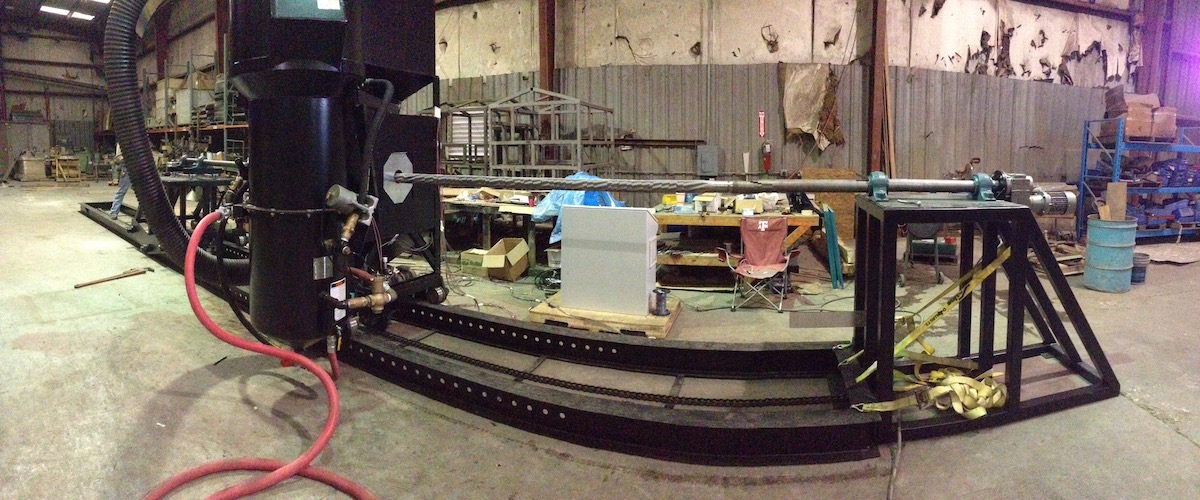

Mud motor and PC Pump Surface Preparation Systems

- Our team has designed and built numerous systems to blast and coat stators and rotors for drilling motors and artificial lifts. Our designs fully enclose the process areas in order to keep all moving parts away from blasting ricochet and overspray damage. This diminishes downtime and maintenance.

- We've learned, through our years serving this industry, the importance of minimizing debond and adhesion failures. Our systems are designed with this in mind so that they produce accurate, uniform and repeatable blast profiles and coating thicknesses.

PID Speed Controlled Winch

- A company specializing in services for tall and difficult to access structures contacted us about cleaning and coating a very tall stack (chimney). This particular stack was over 350 ft tall and 6 feet in diameter. The customer’s wishes were that they would be able to blast and coat the inside of the stack without having an operator inside.

- To accomplish this, Clemtex’s engineering team designed a PID controlled winch to precisely control the speed of the blasting and coating tools that would be suspended inside the stack. The winch was programmable to very precise work speeds to ensure a consistent blast profile and coating thickness.

Plural Component Fluid Mixing System

- Using a unique manufacturing process, this customer applies a two-part coating to a spherical product in a trammel (tumbler similar to a concrete truck). Issues addressed included inconsistent mixing, non-uniform coating application, excessive waste and manual operation for operators.

- Our team designed a comprehensive control system to accurately and efficiently apply their coating. After completion of this system, the product yield increased from 45% to 95%, as well as a significant reduction of waste (clean up solvent) and labor requirements.

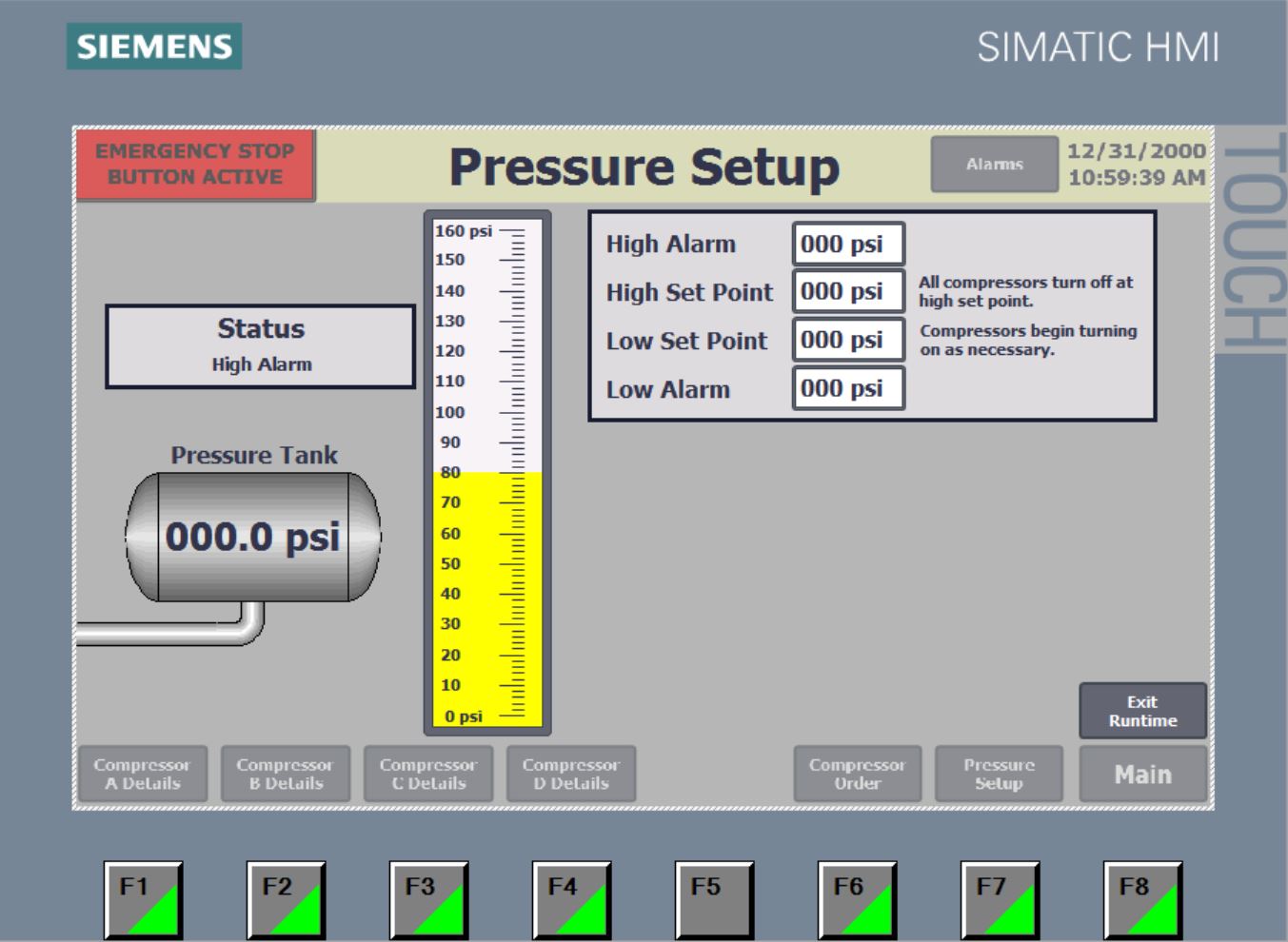

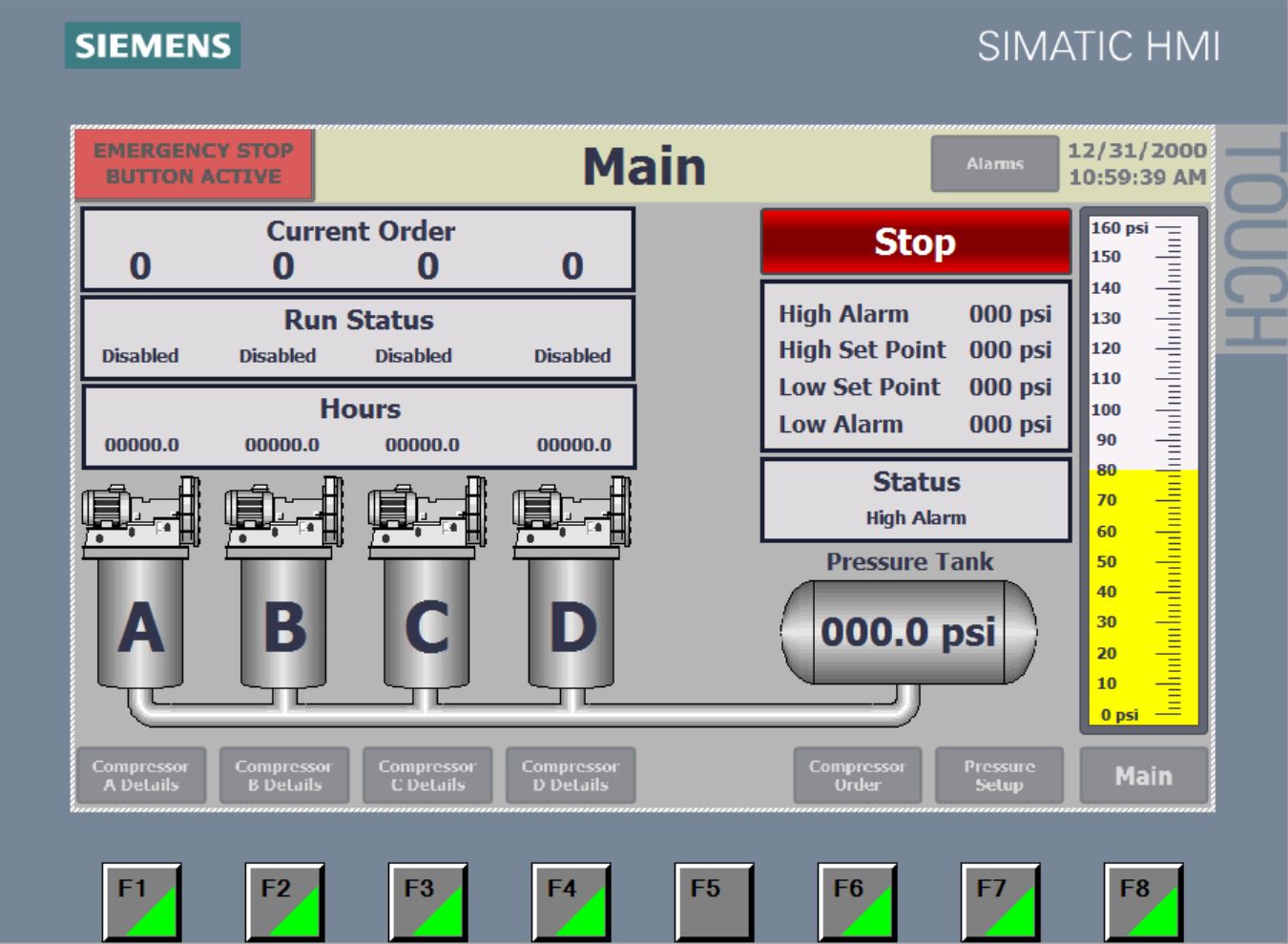

Compressor Control System

- A customer with four independent compressors had issues connecting all compressors to the same plant air system. The lack of communication between compressors caused the system to be extremely inefficient.

- We designed a control system to allow the compressors to communicate effectively as well as rotate the load as necessary to increase efficiency.