As an OEM and integrator, Clemtex has designed machinery and control systems for plant and factory automation since 1992. Our field experiences provide the necessary knowledge to serve a variety of industries and applications.

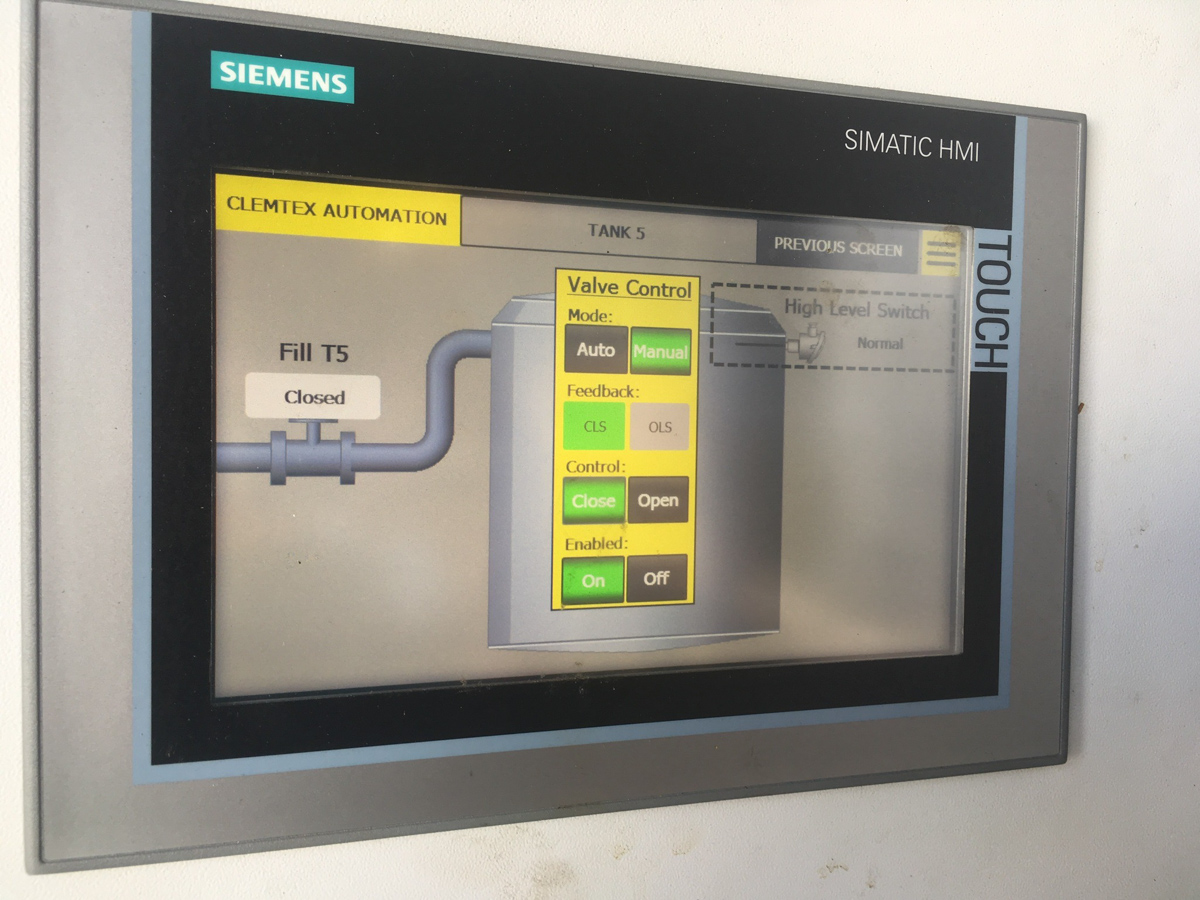

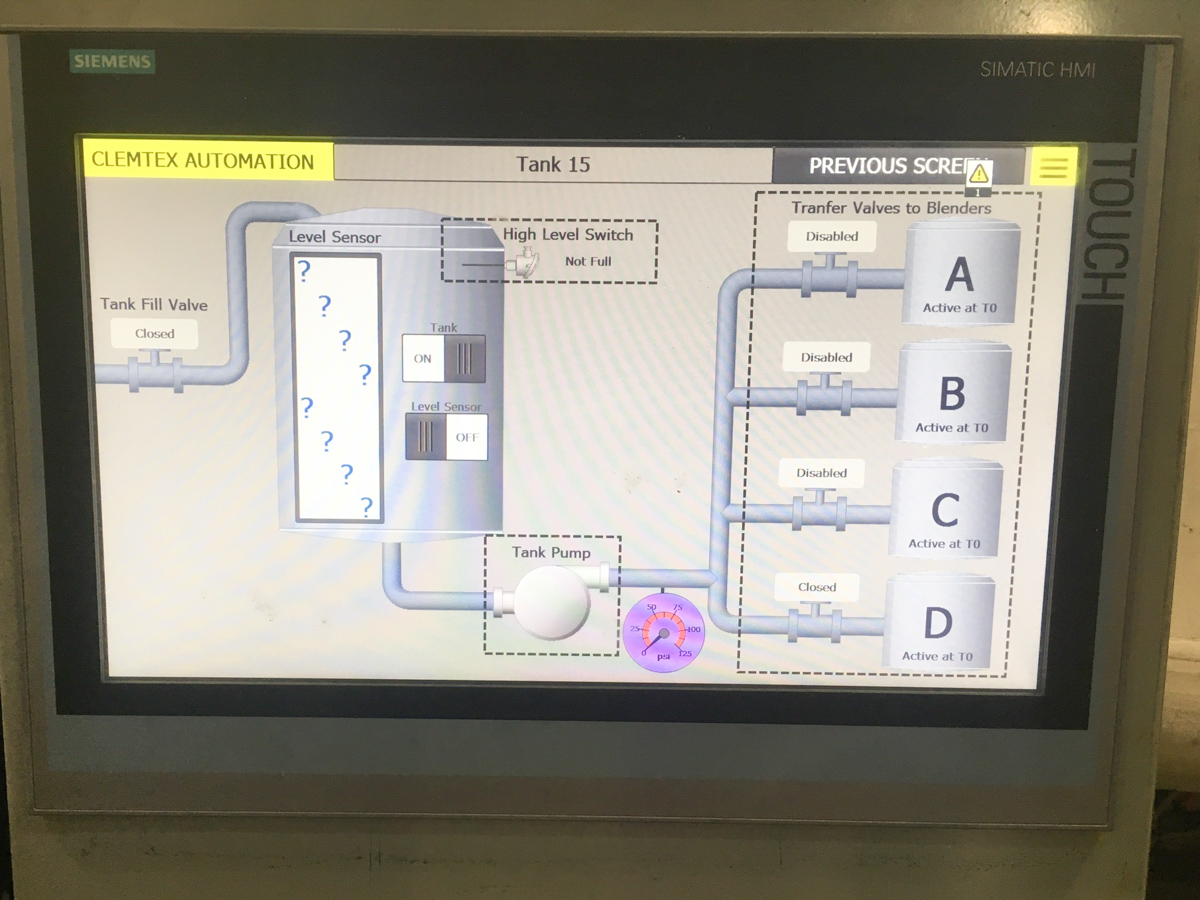

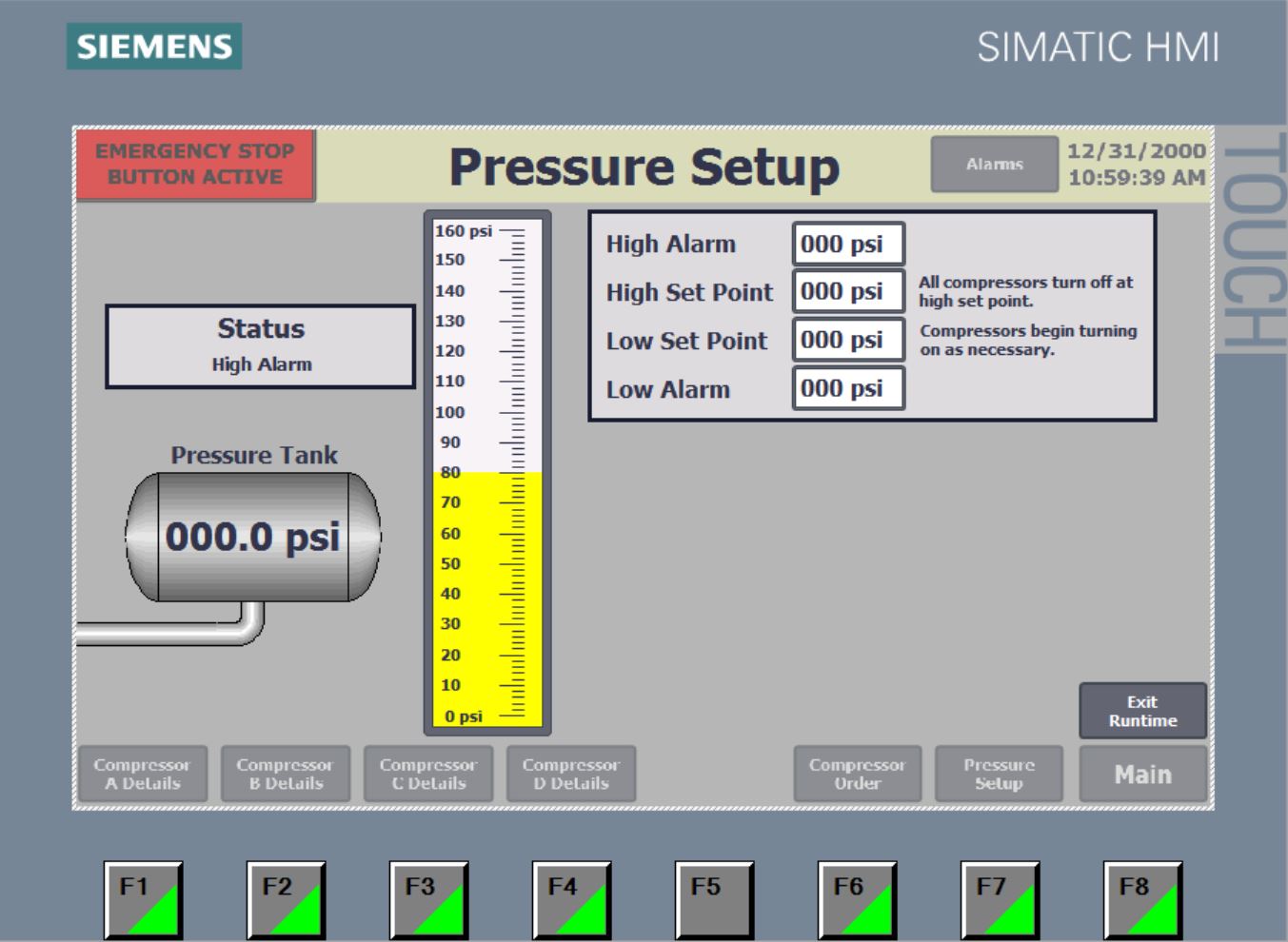

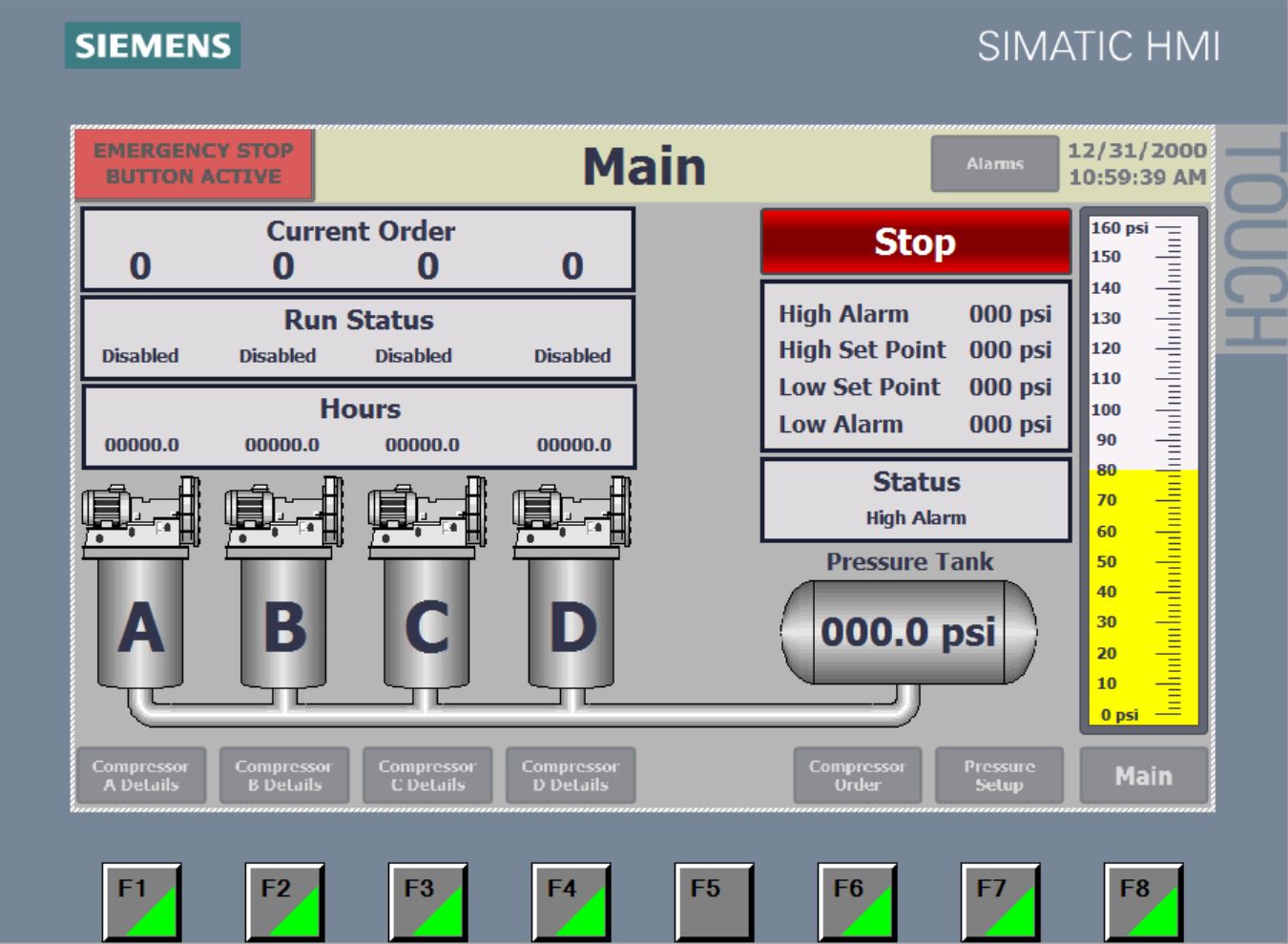

Our focus includes supplying our customers with process control and instrumentation solutions utilizing PLCs, Drives, and HMI systems.

Automation services

Plant Floor & Factory Automation

Process Integration

PLC & HMI Program

Development

Legacy System Upgrades

CAD – 2D & 3D Drawing

and Planning

Project Management

On-site Installation,

Testing and Training

On-site and Remote

Support

Areas of Expertise

- Dense phase and lean phase recovery of fluidized materials

- Use of pneumatic driven vacuum producers, motor powered cyclones and air pressure vessels

- Medias include powders and granular products (abrasive and non-abrasive)

- Recovery/recycling and separation of particle size

- Controlled transfer rate of material in a process

Pneumatic

- Dense phase recovery of heavy material

- Use of augers, belt conveyors and bucket elevators

- Medias include abrasives, shot, metallic and non-metallic

- Recovery/recycling and separation through screening, sieving and air wash

Mechanical

- Media recovery and/or metering for surface preparation

- Inventory and dispensing of materials in chemical process areas

Applications

- Pressure tanks (2 quart to 60 gallon capacity)

- Diaphragm and piston pumps for fast distribution

Pneumatic

- Gear pumps for precise distribution

- Electric piston pumps for high pressure distribution

- Peristaltic pumps for highest precision distribution

Mechanical

- Batch mixing processes

- Precise coating of parts (spray booths and coating lines)

- Precise coating of internal diameter tubes (pipe, stators, risers, etc.)

- Inventory and dispensing of materials in hazardous areas

Applications

- Piston cylinders for lifting and clamping

- 90deg actuators for valve manipulation

Pneumatic

- Motor starters for 1PH and 3PH motors

- Variable frequency drives for 3PH inductive motors

- Servo drives for pulse and servo motors

Mechanical

- Limit switching with use of physical contracts, inductive sensing switches and photoelectric switches

- Linear position feedback using incremental and absolute encoders

- Vertical position feedback using incremental and absolute encoders

- PID loop attenuation and drive speed control

Technology

- Custom designed to customers’ needs

- Control panels and process instrumentation to meet area classifications

- Touch-screen or push button controls

- Detailed process and electrical drawings

- Systems optimized with intuitive operator interface

Design

- Programming designed for easy system expansion

- Turnkey field installation

- Communication with other control systems

- Optional remote and cloud connectivity

Programming and integration

- Position - limit switches

- Level – probes and float valves

- Weight – load cell and stain gauge

- Pressure – pneumatic and fluid measurement

- Flow – Gear and paddle gauges

- Temperature – Probe, thermocouple and thermowell measurement

- Surface treatment – surface profile and coating thickness

Physical

- Position – Inductive, photoelectric and laser

- Level – radar and ultra sonic sensing

- Flow – Coriolis and ultra sonic sensing

- Temperature – inferred transmitting

- Environmental – atmospheric dew point, temperature and relative humidity

Touchless

- Motor and process timers for life information

- Process instrumentation values

- Preventative maintenance reporting

- Warnings and alarms

Logging and reporting

- Data visualization

- Units and metrics

- Built to be scaled easily and deployed quickly