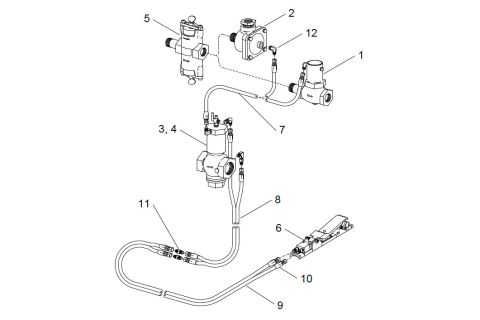

Blast Machine, Classic, 6 cf, Manual Quantum Valve

High-performance, versatile blast cleaning system removes contamination, corrosion, mill scale, and coatings from most surfaces. Produces a uniform surface texture, and creates a surface profile to increase bonding for coatings.

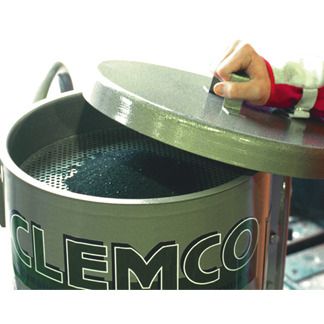

Model 2452 holds 6 cubic feet of abrasive providing 30 minutes of blasting at 100 psi with a No. 6 (3/8") nozzle.

Requirements for Operation

These items are required but not included with this equipment:

- Clean, dry, compressed air of sufficient volume to maintain desired pressure at the nozzle. Refer to Air Consumption Charts.

- Minimum of 50 psi needed to close the pop-up valve and pressurize the blast machine.

- OSHA-required remote control system that interrupts blasting if operator should lose control of the nozzle when blast machine is pressurized.

- NIOSH-approved, type CE, supplied-air respirator.

- Grade D breathing-air supply as defined by Compressed Gas Association Commodity Specification: G-7.1 (Refer to www.cganet.com).

- Abrasive blast media specifically marketed for abrasive blasting and appropriate for your application.

- Appropriate blast suit, work boots, hearing and eye protection.

Description of Operation

The operator controls blasting from a remote control handle at the nozzle. Pressing the handle starts blasting; releasing it stops blasting. The blast machine contains abrasive and meters it into the compressed air stream.

Advantages

- Yard portable, industrial-quality blast machines manufactured to ASME code.

- 1-1/4-inch piping allows up to 50 percent more air flow when compared with 1-inch piping.

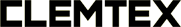

- Industrial-quality valves, piping and fittings designed to maximize air flow and minimize energy required to operate the system.

- FSV abrasive metering valve maintains smooth, consistent, adjustable media flow. Model 2443 Lo-Pot has a LPV abrasive metering valve.

Approvals and Certifications

Clemco's quality management system is ISO 9001-2008 certified.

Blast machine pressure vessel built to American Society of Mechanical Engineers (ASME) specifications for 150-psi working pressure. Vessel is hydrostatically tested and National Board-certified.

Remote control system complies with OSHA regulation 1910.244 (b).

| MPN | 23769 |

|---|---|

| Other Part Number | SBM1187, 01187 |

| Manufacturer | Clemco |

- $1,551.50