All Products

- Automated/Engineered Equipment

- Automated Stator Pipe Internal Blasting Unit

- Bundle I.D. Coating Lance System

- Bundle I.D. Blasting System

- Custom Automated Conveying Equipment

- Custom Blast Machine Controls

- Custom Control/Automation Packages

- Custom Low Pressure Conveying Equipment

- Portable Drive System

- Custom Plural Component Proportioning System

- I.D. Blasting Unit, Rotating Lance

- I.D. Stator Coating Unit

- Rotor Blasting Unit

- Blast Equipment

- Blast and Abrasive Recovery Systems

- Blast Cabinet Replacement Parts

- Blast Cabinets

- Blast Hose and Couplings

- Blast Lighting

- Blast Machines

- Blast Rooms

- Bulk Equipment

- Clemtex Maintenance Unit

- Compressed Air Treatment

- Controls and Valves

- Dust Collection and Air Movement

- Hoods and Respiratory

- I.D. Blasting Equipment

- Nozzles

- Personal Protective and Safety Equipment

- Power Tools

- Reclaim/Media Recovery Systems

- Suction Guns

- Wetblast

- Wheel Machines

- Blast Media

- Spray Equipment

- Compressed Air Treatment

- Consumables

- Cups and Cup Accessories

- Electrostatic Spray Equipment

- Fluid Filters/Screens and Surge Chambers

- Fluid Hose

- I.D. Coating Equipment

- Paint Booths and Ovens

- Paint Tanks

- Plural Component Sprayers

- Respirators and Accessories

- Solvent Recyclers

- Spray Gun Extensions

- Binks Conventional 52-1382

- Binks Conventional 52-2410

- Binks Conventional Style C

- Binks Conventional Style EA

- Binks Conventional Style EAX

- Binks Conventional Style EB

- Binks Conventional Style EBX

- Binks Conventional Style EN

- Binks Conventional Style ENX

- Binks Conventional Style ERX

- Binks Conventional Style HC

- Binks Conventional Style HCVT

- Binks Conventional Style SA

- Binks Conventional Style SC

- Binks Conventional Style SCMBX

- Binks HVLP Mach Series

- Spray Guns

- Air Adjusting Valves

- Air Assist Airless

- Airless

- Airless Handheld

- Cleaning/Dusting

- Conventional

- Electrostatic

- HVLP/LVMP

- Spray Gun Extensions

- Spray Gun Accessories

- Sprayers and Pumps

- Compressed Air Treatment

- Hose and Fittings

- Blast Hose

- Ball Valves, Standard

- Ball Valves, VA Series

- Blast Hose Couplings

- Camlock Fittings

- Crowsfoot Connections

- Fluid Hose, High Pressure

- Fluid Hose, Low Pressure

- Gaskets and Washers

- General Purpose Air Hose

- High Pressure Nipples

- High Pressure Plugs

- High Pressure Swivel Adapters

- Hood Breathing Hose

- Industrial Interchange/Quick Disconnect

- King Combination (KC) Nipples

- Low Pressure Nipples

- NPS Female Threaded Hose End

- Push-to-connect Fittings

- Spray Air Hose

- Thread Adapters/Filter Housings

- Twinline Hose

- Vacuum Hose

- Personal Protective and Safety Equipment

- Pipe Blasting and Coating Equipment

- Test Equipment

- Adhesion Testers

- Anchor Pattern Test Equipment

- Climate Monitoring

- DFT Coating Thickness Standards

- Dry Film Thickness Gauges

- Efficiency Test Equipment

- Holiday/Pinhole Detectors

- Kits

- PosiTector SmartLink

- Steel Shot Peening Intensity

- Substrate Testing

- Surface Contamination

- Wet Film Thickness Gauges

- Refurbished Equipment and Specials

- Featured Products

Our UPS Shipping integration with the website is broken. To place orders, please call or submit an inquiry on the contact us page.

- Home

- Clemtex Corner

- I.D. Spray Equipment

- Pipe Coating: How fast do I pull?

Have you ever had trouble figuring out the spray speed when coating the internal diameter (I.D.) of a pipe? Don't worry, everyone has. Many perform trial run after trial run to determine the proper speed to pull back their coating tool. Here we will show you how with a couple of simple calculations and some marks on your hoses as a reference, you can be applying a consistent coating in no time.

In order to run the calculations, you must first determine the flow rate of you coating tool. Use a timer and a measuring beaker to determine the ounces after 30 seconds of spray time. Make sure your atomization air is off when doing this!

In order to run the calculations, you must first determine the flow rate of you coating tool. Use a timer and a measuring beaker to determine the ounces after 30 seconds of spray time. Make sure your atomization air is off when doing this!

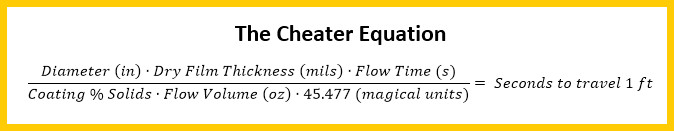

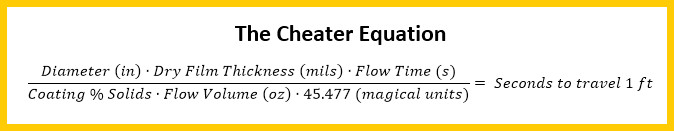

Now, using the internal diameter of your pipe, the dry film thickness you wish to achieve, the coating percent solids, your flow volume, and your flow time (30 seconds) you can determine the time it should take for your tool to travel 1 lineal foot. The equation above shows you how to calculate this manually, or you can use our I.D. Coating Speed Calculator here.

Next you should tape off markings every foot on the hose that leads to your coating tool. Now, your operator knows that he should reach each tape marking in about 1.4 seconds (using the default numbers found in on the I.D. Coating Speed Calculator page).

Now, using the internal diameter of your pipe, the dry film thickness you wish to achieve, the coating percent solids, your flow volume, and your flow time (30 seconds) you can determine the time it should take for your tool to travel 1 lineal foot. The equation above shows you how to calculate this manually, or you can use our I.D. Coating Speed Calculator here.

Next you should tape off markings every foot on the hose that leads to your coating tool. Now, your operator knows that he should reach each tape marking in about 1.4 seconds (using the default numbers found in on the I.D. Coating Speed Calculator page).

In order to run the calculations, you must first determine the flow rate of you coating tool. Use a timer and a measuring beaker to determine the ounces after 30 seconds of spray time. Make sure your atomization air is off when doing this!

In order to run the calculations, you must first determine the flow rate of you coating tool. Use a timer and a measuring beaker to determine the ounces after 30 seconds of spray time. Make sure your atomization air is off when doing this!

Now, using the internal diameter of your pipe, the dry film thickness you wish to achieve, the coating percent solids, your flow volume, and your flow time (30 seconds) you can determine the time it should take for your tool to travel 1 lineal foot. The equation above shows you how to calculate this manually, or you can use our I.D. Coating Speed Calculator here.

Next you should tape off markings every foot on the hose that leads to your coating tool. Now, your operator knows that he should reach each tape marking in about 1.4 seconds (using the default numbers found in on the I.D. Coating Speed Calculator page).

Now, using the internal diameter of your pipe, the dry film thickness you wish to achieve, the coating percent solids, your flow volume, and your flow time (30 seconds) you can determine the time it should take for your tool to travel 1 lineal foot. The equation above shows you how to calculate this manually, or you can use our I.D. Coating Speed Calculator here.

Next you should tape off markings every foot on the hose that leads to your coating tool. Now, your operator knows that he should reach each tape marking in about 1.4 seconds (using the default numbers found in on the I.D. Coating Speed Calculator page).

0 Comment(s)

Categories

- I.D. Spray Equipment (6)

-

I.D. Blast Equipment

(5)

- Spinblast Tool (3)

- Spray Booths (1)

-

Testing Equipment

(3)

- Dry Film Thickness (1)

- Anchor Profile (2)

- Humidity and Dew Point (1)

- Holiday Detectors (1)

- Surface Testing (0)

-

Coating/Painting Equipment

(12)

- Respirators (7)

- Spray Guns (2)

- Airless Pumps (1)

- Electrostatic Spray (1)

- Newsletter (2)

- Blast Cabinets (3)

-

Blasting Equipment

(19)

- Hoods & Respiratory (10)

- Wet blast (3)

- Blast Rooms (1)

- Blast Machines (1)

- Compressors (1)

- Blast Cabinets (1)

- Engineered/Automated Equipment (6)

- PPE (7)

- Holiday Hours (2)

- Graco (0)

- Announcements (7)

-

Abrasives

(2)

- Green Diamond (1)

- Sure/Cut Velocity (1)

Recent Posts

Archive

Tags

rpb

clemco

nova 3

defelsko

positest

bullard

t150

wetblast

nova 2000

c40

clemtex

binks

graco

blast cabinet

green diamond

ducting

global finishing solutions

smartlink

econoline

dust collector

cmu

maintenance unit

cool vest

trophy

lvmp

co monitor

rtr

testex

flex

wet blast

xforce

airless

t100

t-series

spectrum

millennium 3000

apollo 600

apollo 60

genvx

88vx

zero

sabre

e-xtreme

lpd

z-link

px4

respirators

spincoater

hdcbx360

pipe